How Printing and Packaging Companies Enhance Product Visibility

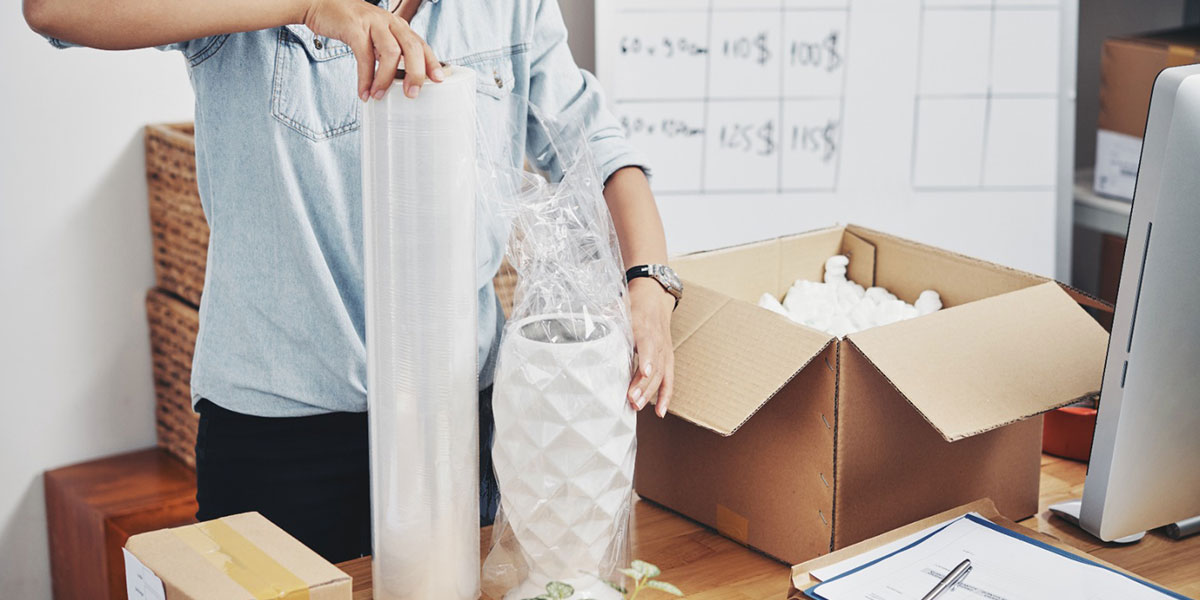

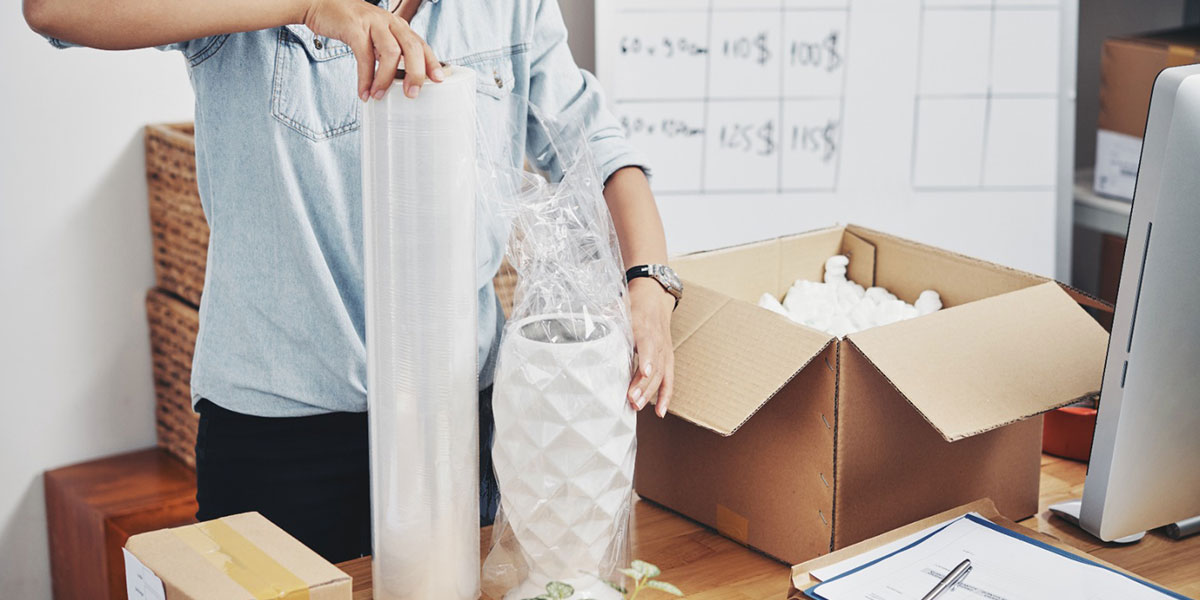

Product visibility is built through careful planning, not branding alone. Printing and packaging companies influence how a product is perceived by aligning design with material choice and print execution.

From the ink applied on a label to the layered construction of cartons and flexible packs, each element plays a role in how products and packaging stand out, communicate information, and maintain visual consistency on the shelf.

For any packaging company, this work begins well before printing starts. Material behavior, surface finish, durability, and functionality all shape the final appearance of the pack.

When these factors come together effectively, packaging supports both protection and presentation.

In this blog, you will explore how printing technologies and packaging materials combine to enhance product visibility.

Printing is the most immediate touchpoint between a brand and its audience. Color accuracy, ink adhesion, finish, and durability determine whether packaging communicates quality or fades into the background.

High-performance inks and coatings ensure sharp graphics, resistance to smudging, and compliance with food and pharma safety standards.

In essence, specialty inks, adhesives, and coatings become essential to modern printing and packaging companies.

Without advanced ink formulations, even the best designs fail to perform across diverse substrates such as films, paperboard, or aluminium foil.

A packaging company focused on visibility must prioritize chemical precision as much as visual appeal.

Within the integrated ecosystem of GLS Speciality Chemicals support printing and lamination processes by delivering consistent ink performance across flexible, rigid, and aseptic formats.

These formulations ensure that products and packaging maintain visual integrity throughout transportation, storage, and retail display.

Printing does not operate in isolation. The surface on which ink is applied plays a decisive role in the final appearance of a package.

Broadly, printing substrates fall into paperboard, flexible films, and multilayer aseptic structures.

Paperboard remains a preferred choice for cartons and aseptic packs due to its excellent printability and structural stiffness.

In aseptic packaging, it forms the outer layer that supports clean, high-definition graphics while contributing to pack strength.

On its own, however, paperboard cannot provide the barrier protection or shelf life required for sensitive products.

Flexible packaging films, particularly PET and metallised PET, dominate modern retail because of their gloss, clarity, and barrier properties.

These films are critical for printing and packaging companies to enhance shelf presence and preserve freshness.

As part of GLS Group, GLS Polyfilms’ in-house production positions the company among leading polyester film manufacturers in India and PET film manufacturers in India, enabling consistent thickness, clarity, and lamination strength.

This integrated approach allows products and packaging to achieve both visual appeal and functional reliability, giving any packaging company the tools to create standout, durable, and safe packaging solutions.

Aseptic packaging represents one of the most advanced intersections of printing and material science.

A typical aseptic pack consists of six layers, each performing a specific function. While the outer paperboard layer enables high-quality printing, internal layers ensure barrier protection, strength, and food safety.

One of the most critical layers in aseptic packaging is aluminium foil. Though invisible to the consumer, it protects products from oxygen, light, and moisture, directly impacting shelf life and brand reliability.

The quality of aluminium foil influences not only protection but also how well outer layers maintain shape and print finish.

Recognized among top aluminium foil manufacturers in India, GLS Aluminium supports aseptic, pharma, and flexible packaging applications with precision-engineered foils.

Within GLS Group, aluminium integrates seamlessly with films, inks, and laminates, enabling printing and packaging companies to deliver packaging that looks premium and performs under demanding conditions.

Flexible packaging has transformed how brands approach visibility. High-gloss finishes, metallised effects, and tactile coatings allow packaging to stand out instantly.

PET and BOPET films support advanced printing techniques such as rotogravure and flexography, enabling vibrant colors and fine details.

A forward-thinking packaging company understands that flexible packaging is not just about material cost, but about how surface aesthetics influence buying decisions.

This is why products and packaging in flexible formats rely heavily on precision film manufacturing and lamination compatibility.

With its in-house film manufacturing capabilities, GLS Group ensures that packaging films support both visual enhancement and functional durability. These films serve as the canvas on which printing excellence is built.

Behind every visually striking package lies chemistry that holds everything together. Adhesives bond layers, coatings protect prints, and inks define brand identity. Without chemical compatibility, delamination, fading, or contamination risks increase.

Specialty chemicals are therefore a silent driver of visibility and compliance. Food-safe inks, low-migration adhesives, and durable coatings ensure that products and packaging meet global standards while retaining visual appeal.

The specialty chemicals division within GLS Group develops inks and adhesives tailored for printing and lamination, supporting the evolving needs of printing and packaging companies across food, pharma, and consumer sectors.

Innovation in packaging is not always visible, but its impact is. R&D-led improvements in films, foils, inks, and recyclability allow brands to differentiate without compromising sustainability.

As regulations tighten and consumers demand responsible packaging, visibility must align with environmental performance.

A modern packaging company must balance shelf appeal with recyclability, downgauging, and resource efficiency. Integrated manufacturing ecosystems make this balance achievable.

By combining films, aluminium, specialty chemicals, and testing capabilities, GLS Group enables packaging solutions that enhance visibility while supporting circular economy goals.

This integration reduces dependency gaps and improves consistency across products and packaging formats.

Ultimately, product visibility depends on seamless coordination between materials, printing, and performance.

GLS Group brings all of these capabilities under one roof, managing every stage of the packaging process, from ink formulation and specialty coatings to BOPET film lamination, aluminium foil integration, and paperboard structuring.

Whether it is a printed carton, a flexible pouch, or an aseptic pack, GLS ensures perfect harmony among all components, allowing products and packaging to stand out on shelves, maintain durability, and inspire consumer confidence, all without relying on external partners.

Product visibility is made through careful planning and execution. It relies on the seamless integration of printing technologies, substrates, and materials to make packaging stand out.

For any packaging company looking to capture attention, combining innovation with precise execution is essential.

As printing and packaging companies evolve, leveraging integrated expertise, spanning inks, films, aluminium foils, and specialty chemicals, ensures products and packaging not only attract the eye but also deliver durability and trust.

When all components work in harmony, packaging becomes a powerful tool for differentiation.

Connect with GLS Group to create packaging that elevates your brand presence and shelf impact.

1. How do printing and packaging companies enhance product visibility?

Printing and packaging companies enhance visibility by combining high-quality inks, advanced substrates, and material innovation. Thoughtful design, structural integrity, and surface finishes ensure that products and packaging attract attention and communicate brand value on the shelf.

2. What materials are commonly used in product packaging?

Common materials include paperboard, flexible films like PET and BOPET, aluminium foils, and specialty coatings. Each material contributes to durability, printability, barrier properties, and overall shelf appeal for products and packaging.

3. Why is integrated packaging important for a packaging company?

Integrated packaging ensures that all elements, inks, films, foils, and adhesives, work in harmony. This approach enhances product protection, print quality, and shelf appeal, enabling a packaging company to deliver consistent results without relying on multiple partners.

4. How do films and foils improve packaging performance?

High-quality films and aluminium foils protect contents from moisture, light, and oxygen while allowing high-definition printing. They enhance both functionality and visual appeal, which is essential for printing and packaging companies aiming to make an impact in the market.

5. How can a company improve its products and packaging for better shelf presence?

Companies can improve visibility by selecting the right combination of substrates, inks, and coatings, ensuring precise printing, and leveraging durable, visually appealing films and foils. Consulting experienced printing and packaging companies helps optimize packaging design and performance.

© 2025 GLS Group. All Right Reserved.

Powered by ITPL